Precision Engineering from Taiwan

MIT-Grade Manufacturing Excellence with Guaranteed Quality

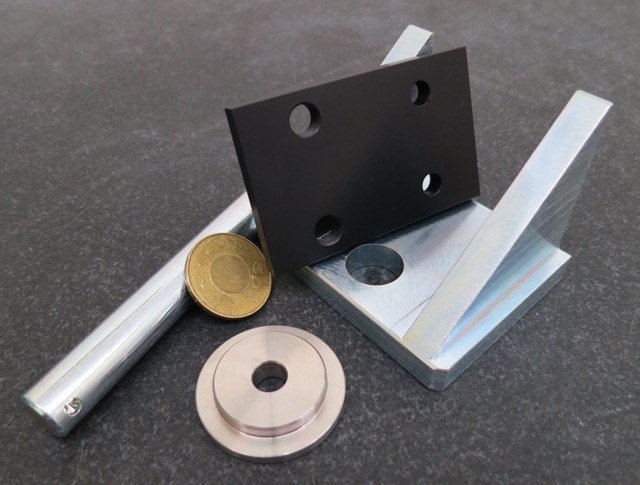

Precision Engineering from Taiwan2

MIT-Grade Manufacturing Excellence with Guaranteed Quality2

Precision Engineering from Taiwan3

MIT-Grade Manufacturing Excellence with Guaranteed Quality3

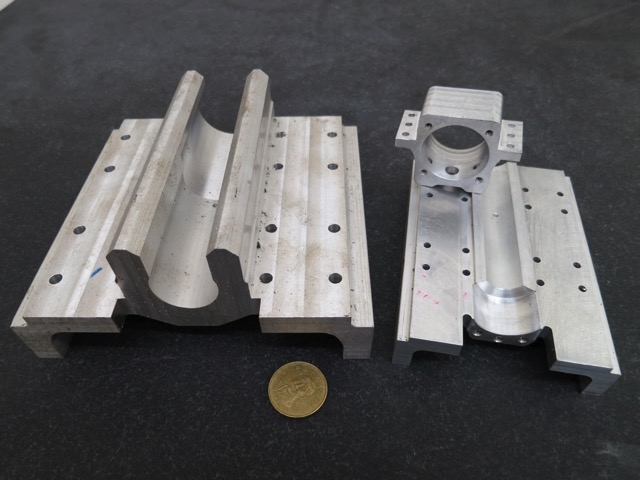

Electric Industry Applications

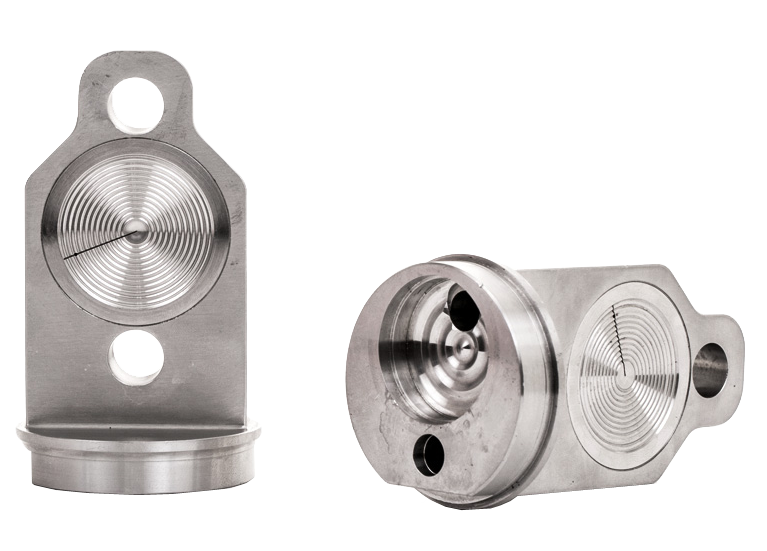

Assembly Parts

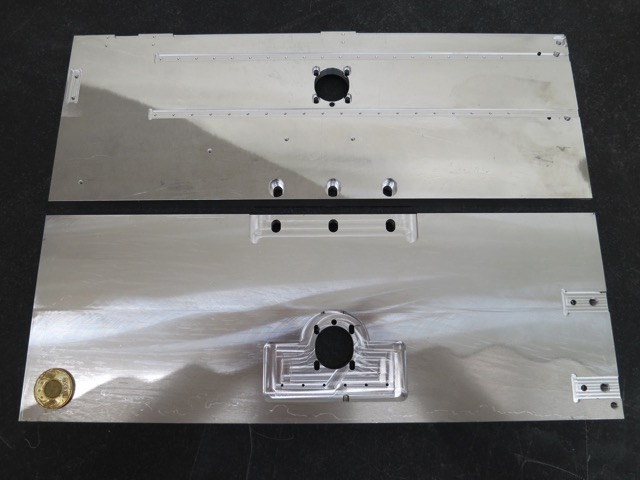

Electric Industry Applications

Extrusion parts

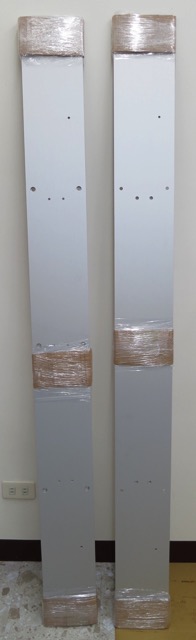

Quality assurance

Quality assurance